"Made in Germany" in the digital and green transformation

From product development via manufacturing up to professional recycling – in modern production, quality assurance is becoming a permanent task and is dependent on efficient and reliable digital processes. One question that was discussed at the first QI-Digital Forum in Berlin on 11 October 2022 was which digital tools (from so-called SMART standards to digital certificates) will be able to support quality assurance. This led to discussions about how efficient they have to be. At the Physikalisch-Technische Bundesanstalt (PTB) and online, a total of 300 participants discussed which challenges the digital green transformation will bring about for quality infrastructure (QI).

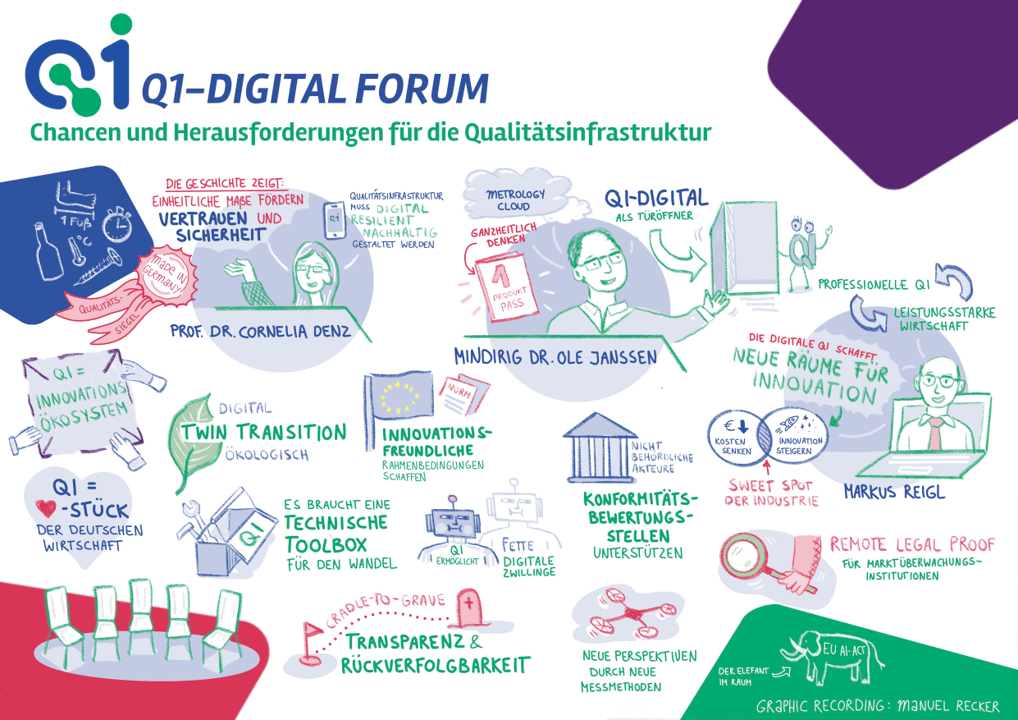

In her welcoming speech, Professor Dr. Cornelia Denz, President of PTB, highlighted the system of QI in Germany which has been established over many years and is trusted all over the world. The “Made in Germany” label stands for this. Professor Denz also pointed out that QI must now be further developed in a digital, resilient and sustainable way so that the trust people have in these products today will also be ensured in the future. In his speech, Dr. Ole Janssen of the BMWK (Federal Ministry for Economic Affairs and Climate Action) argued that this topic should be viewed in its entirety. For example, the introduction of so-called digital product passports (DPPs) has been proposed. These DPPs will contain all information – from data on raw materials to recycling – that is necessary to enable an environmentally conscious circular economy.

Room for Innovations

Markus Reigl, Head of Corporate Standardization at Siemens, summed up what industry expects from a digital quality infrastructure: “More innovation, fewer costs!” Digitalization is making room for innovation. This, in turn, can advance the economy. In the panel discussion on “QI-Digital – Made in Germany in der digitalen und grünen Transformation” (QI-Digital – Made in Germany in the digital green transformation), Mr. Reigl explored a number of issues with Prof. Dr. Gisela Lanza from the Karlsruhe Institute of Technology (KIT), Prof. Dr. Knut Blind from TU Berlin, Dr. Thomas Holtmann from the Federation of German Industries (BDI), Boris Böhme from the Federal Ministry for Economic Affairs and Climate Action (BMWK) and Christoph Winterhalter, Chairman of the Executive Board of the Deutsches Institut für Normung (DIN – the German Institute for Standardization) along with other key players from their field. They focused on the requirements that are being placed on QI from the perspectives of different stakeholders. What is especially important is to create innovation-friendly framework conditions.

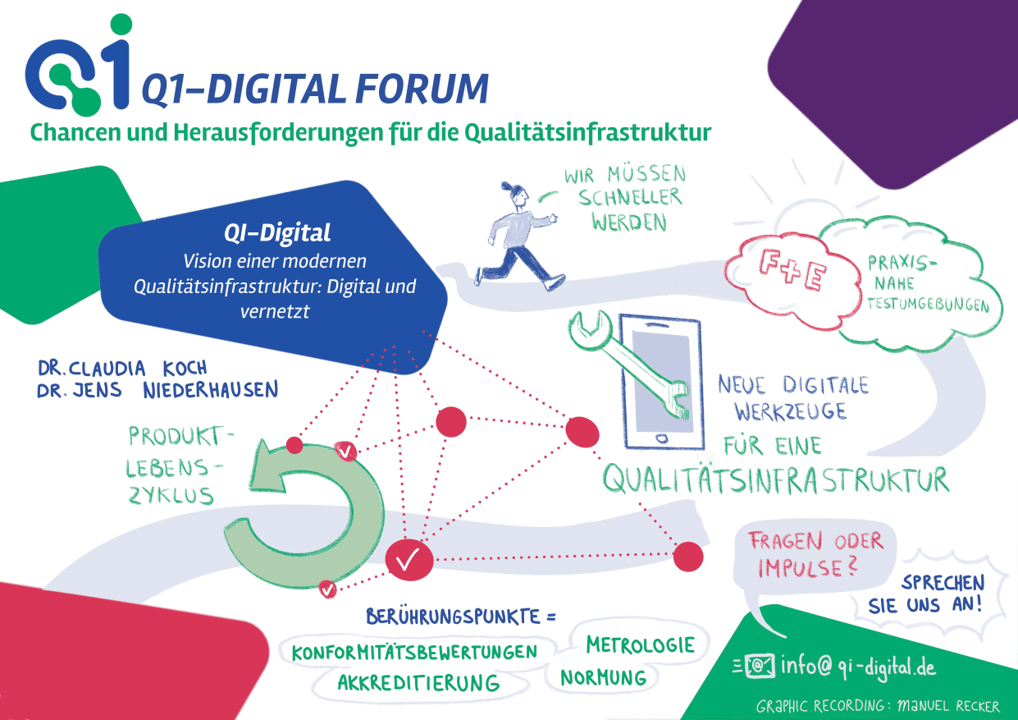

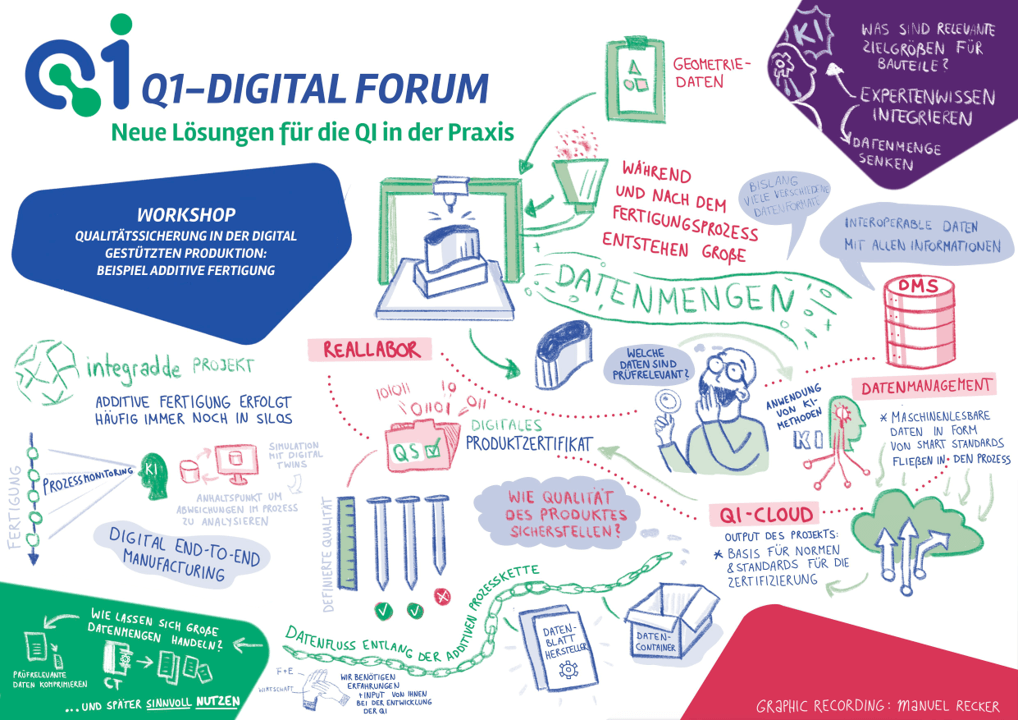

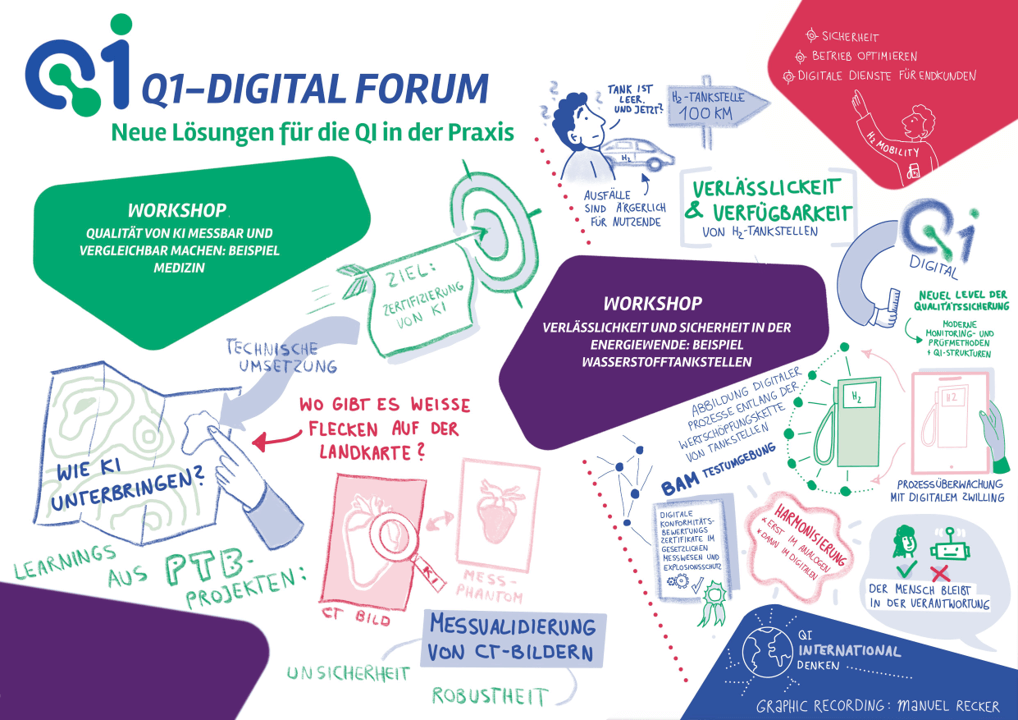

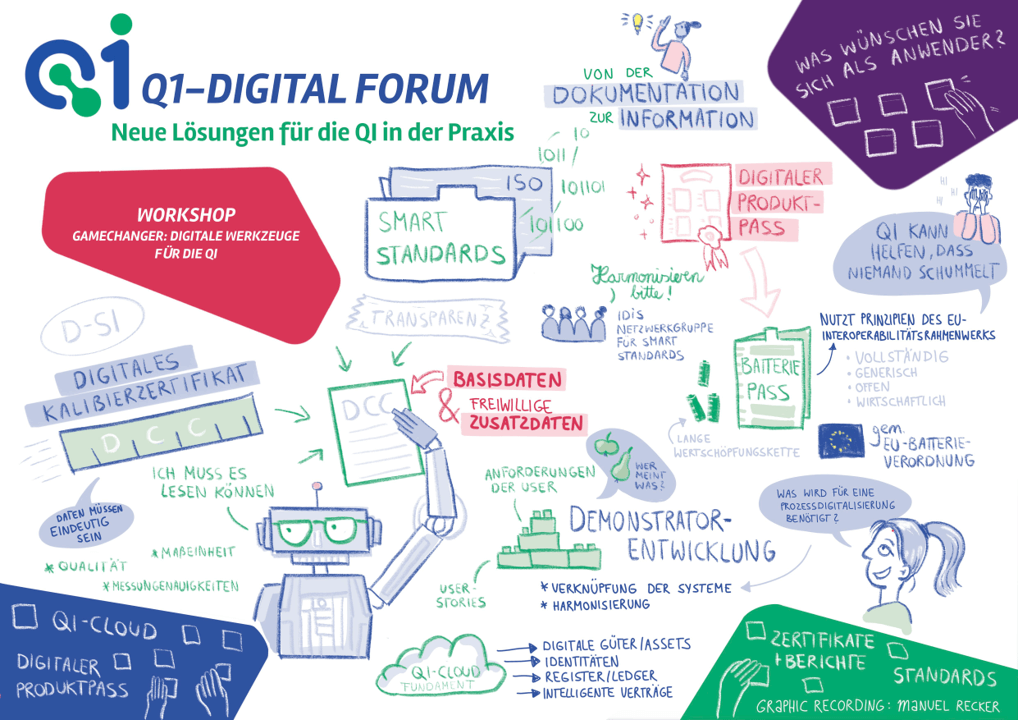

Dr. Claudia Koch from the Federal Institute for Materials Research and Testing (BAM) and Dr. Jens Niederhausen (PTB) outlined what the digitalization of QI as an interaction of conformity assessments, metrology, accreditation, standardization and market surveillance might look like. A digital and interlinked QI needs new solutions and compatible tools, including the DCC, conformity certificates, eAttestation, SMART standards and a QI Cloud. A digital representation, such as a digital product passport, accompanies a product from its development and its manufacturing, to its operation and any possible modifications, up to the recycling at the end of its life over the duration of its entire life cycle. As part of the QI-Digital Initiative, these tools and quality assurance methods are being developed and tested within the scope of three applications. These were then discussed in detail in workshops which were held in the afternoon.

Vision of a digital Quality Infrastructure

What is needed for the digitalization of a work process? In order to find an answer to this question, a further workshop was held that was focused on all digital tools of quality infrastructure. Standards, certificates and reports have to be machine-readable in every case and access to quality information has to be independent of time and location. At the same time, trustworthiness always has to be ensured. Further proposals were made, such as being informed quickly and immediately in the case of standard changes so that the necessary measures can be taken. Participants said that it would also be helpful to be able to simply integrate data into other systems and to be able to revoke the validity of certificates.

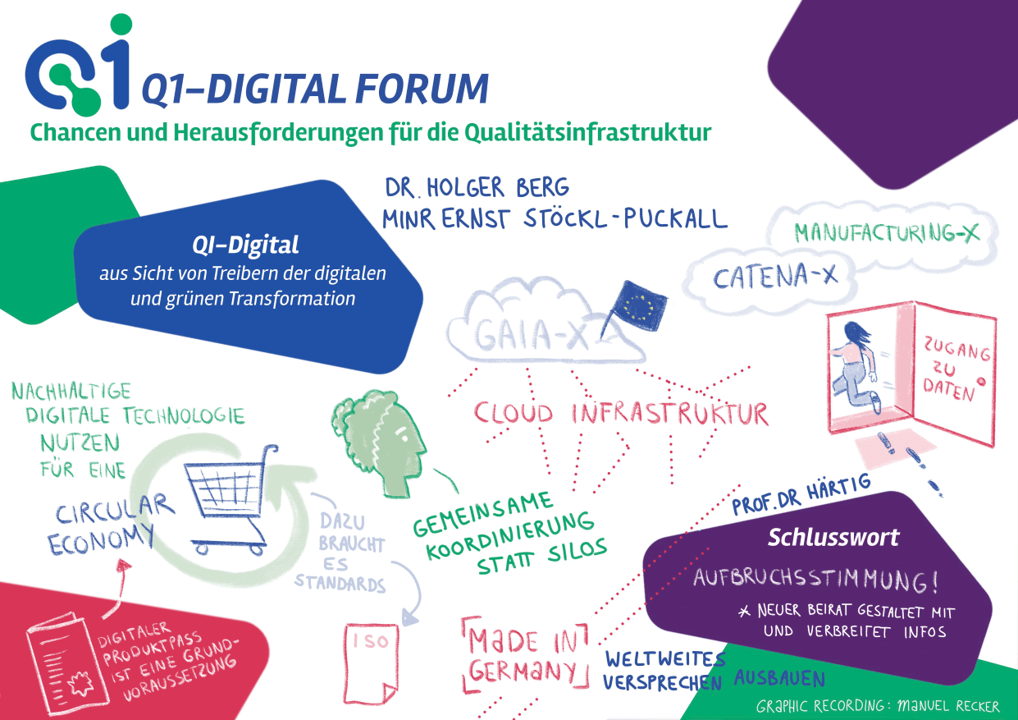

With regard to the digital green transformation of quality infrastructure, Dr. Holger Berg from the Wuppertal Institute for Climate, Environment and Energy and Ernst Stöckl-Pukall from the BMWK jointly stressed once again the central role of a digital product passport for the circular economy. They said that data access and data use as well as interconnections all along the value chain would be essential for this. For this reason, the accruing of isolated data silos would have to be avoided and the existing digitalization initiatives would have to be coordinated.

After having thanked all the participants and the advisory board that had been founded on the day before, Prof. Dr. Frank Härtig (PTB) concluded the Forum. The spirit of motivation and the suggestions from the QI-Digital Forum will now give impetus to the further work of the QI-Digital Initiative and its stakeholders. As a result, the label “Made in Germany” will continue to be a worldwide promise of quality and safety.

Photo Gallery